Bluewall Readymix Plaster in best alternative against traditional On site mixing and Procurement procedure for plastering, Bluewall Readymix plaster is manufactured with well graded sand along with best quality cement and polymer based additives.

Bluewall Readymix Plaster in best alternative against traditional On site mixing and Procurement procedure for plastering, Bluewall Readymix plaster is manufactured with well graded sand along with best quality cement and polymer based additives.

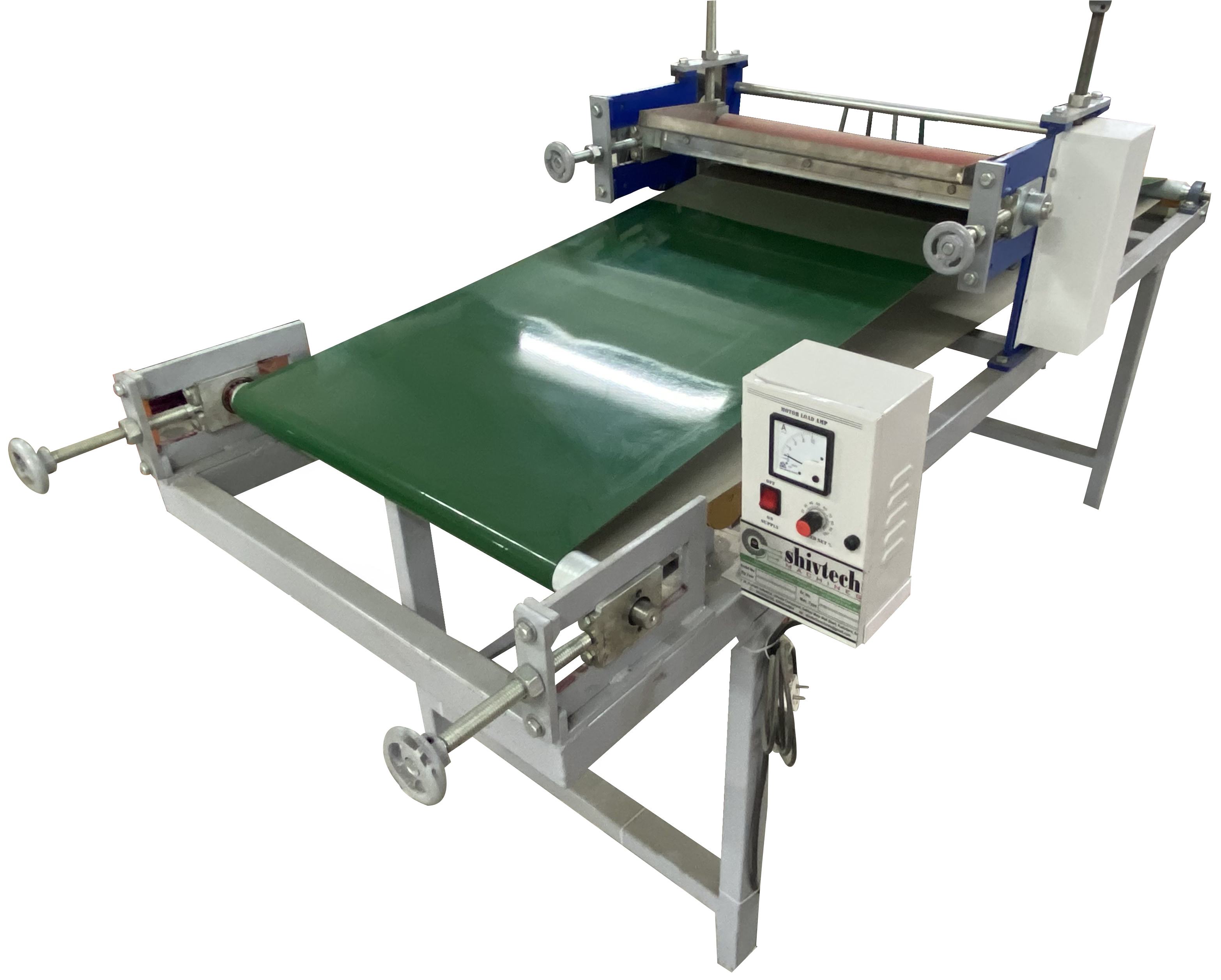

A gumming machine is a specialized piece of equipment designed to apply adhesive or glue to various materials in a controlled and uniform manner. This machine is widely used in industries such as printing, packaging, and textiles for tasks like applying glue to paper, cardboard, labels, envelopes, or fabric edges. The gumming process involves dispensing a thin, even layer of adhesive onto the surface, ensuring optimal bonding and reducing waste. These machines are available in manual, semi-automatic, and fully automatic versions to cater to different production requirements.

Read MoreA gumming machine is an essential industrial device designed to apply adhesive or glue evenly onto a wide range of materials, such as paper, cardboard, fabric, and labels. Its primary function is to ensure precise and consistent adhesive application, making it a critical tool in industries like printing, packaging, and textiles. By automating the gluing process, gumming machines not only improve productivity but also guarantee uniform coverage, enhancing the quality of the final product.

These machines work by using a system of rollers or applicators that distribute the adhesive over the material’s surface. They are equipped with glue reservoirs, control systems, and adjustable settings to handle varying thicknesses, materials, and adhesive types. Depending on the production needs, gumming machines are available in manual, semi-automatic, and fully automatic models. Advanced models often include features like speed adjustment, automatic feeding, and easy-clean systems for enhanced operational efficiency and user convenience.

| TECHNICAL SPECIFICATION | |

|---|---|

| Power : | 1.5kW |

| Frequency : | 50Hz |

| Automation Grade : | Automatic |

| Minimum Order Quantity : | 1 |

| Country of Origin : | Made in India |

Gumming machines are available in several types, each designed to cater to specific applications:

Gumming machines are widely used in various industries for tasks that require adhesive application. Common applications include:

Gumming machines offer several advantages, making them indispensable in modern manufacturing processes:

In summary, a gumming machine is a vital tool in industries requiring precise and efficient adhesive application. Its ability to automate and streamline the gluing process ensures consistent results, reduces material waste, and enhances productivity. With various models available to meet different production needs, gumming machines are an invaluable asset for businesses focused on quality, efficiency, and scalability in their manufacturing processes.